Staying safe at sea means having the proper gear and ensuring that everything will work as planned in the event of an emergency. This article is an excerpt from Safety at Sea, published by US Sailing (published May 2014)

All safety gear must be up-to-date, inspected and properly stowed with a posted chart near the chart table or the companionway to show locations in an emergency. The entire crew should know what safety gear is available, where it is stowed and how to use it. The gear on board a vessel must not only meet the minimal definition for what is required but must also be sized correctly for the vessel. The gear is selected to allow the skipper and crew of a vessel to remain safe at sea and to fetch a safe harbor.

The following is a guide to the safety gear needed for an offshore passage.

PERSONAL SAFETY GEAR

Life Jackets: Inflatable life jackets require daily as well as semi-annual inspections. Since previously inflated life jackets can look just like those that are ready for use, crewmembers have to ensure that the CO2 cylinder has not been punctured. This is easier with recent 1F or 3F inflators that show a “Good to Go” green indicator through a transparent window. If you have a life jacket with an older inflator, take the time to pull open the shroud and inspect the small end of the cylinder. Also, make sure the life jacket fits properly and is in good repair.

Life Jackets: Inflatable life jackets require daily as well as semi-annual inspections. Since previously inflated life jackets can look just like those that are ready for use, crewmembers have to ensure that the CO2 cylinder has not been punctured. This is easier with recent 1F or 3F inflators that show a “Good to Go” green indicator through a transparent window. If you have a life jacket with an older inflator, take the time to pull open the shroud and inspect the small end of the cylinder. Also, make sure the life jacket fits properly and is in good repair.

Life jacket lights should have their batteries checked. Whistles should be attached with lanyards. Strobes and flashlights should be checked for operation. And if the gear hasn’t been used for six months or a year, replace the batteries, regardless of how bright the lights appear to be.

Harnesses and tethers: Tethers can either be integrated into an inflatable life jacket or used separately. Harnesses have to fit correctly, which means that they should be a few inches below the armpits, but not down near the small of the back. They should also be snug around the chest, not so tight that they constrict breathing, but snug enough so they are unlikely to be pulled over one’s head if they come under load.

Tethers should have an overload “flag” that shows if the tether has been previously subjected to high loads. If the overload flag is showing, the tether must be replaced. Also, check for the smooth operation of the snaps at each end of the tether. If you’re using a tether with a “cow hitch” attachment to the harness, ensure that the tether cutter is in place on the life jacket and that it is sharp.

MAN OVERBOARD

Lifesling: Open the Lifesling bag and remove it and its retrieval line from the bag. Stretch the line out on a dock, or trail the lifesling behind a vessel under sail and ensure that the line pays out correctly. Make sure the bitter end is attached to a cleat, padeye or base of a stanchion. Flake the Lifesling line down the center compartment into the bag; don’t coil it. Put the Lifesling in last, ensuring that the covered portion of the retrieval line is all that shows outside the bag. Test the operation of the light and replace batteries if necessary.

MOM (Man Overboard Module) and DAN Buoy: MOMs should be serviced every two years by a certified repacker. The repacker will verify that the inflation mechanisms are ready to go, that the batteries are replaced, and that the MOM hasn’t been damaged between inspections. DAN Buoys can be owner-serviced. Refer to the information supplied with the DAN Buoy for specific repacking instructions. For any piece of gear that can be owner-serviced, ensure that you have the correct rearming kits aboard.

BOAT SYSTEMS

All systems should be checked before any voyage and labeled appropriately for use in an emergency by those unfamiliar with the items. Manuals should be collected in a central location for reference. The following systems in particular need attention: fuel tanks clear of debris that tends to settle, but will clog lines when agitated in a seaway; steering cables and hardware; fresh water tanks filled and treated with very diluted bleach (or similar); bilge pumps—one on deck, one below—, operational with spare diaphragms; fire suppression systems appropriately distributed and currently inspected; battery isolation system functional.

Navigation Lights and Spares: Vessels racing in a ISAF Category 0, 1, or 2, or a US Sailing ocean race, are required to have a second set of navigation lights. Generally, sailboats will have a set of deck-level lights that are used with a masthead light when under power, and a tricolor masthead light when under sail. If your boat has only a single set of navigation lights, you need to have the ability to rig a second set, either by using portable lights or lights that operate off the vessel’s electrical system. In either case, both sets of navigation lights must be Coast Guard and/or COLREG standard, and each set should be powered independently so that a single failure doesn’t cause both sets of lights to fail.

Clean Tanks and Engine Maintenance: The greatest test of most auxiliary propulsion systems is when a boat is in a storm. In particular, debris from diesel tanks can be stirred up sufficiently to clog fuel filters and bring the engine to a premature halt. While crewmembers can remove and replace filters, and bleed the engine’s fuel system, it’s not undertaken lightly when in a storm. This can be virtually eliminated by maintaining the cleanliness of fuel systems, especially fuel tanks, and polishing the fuel if necessary.

UNDERWAY

Part of any watch rotation should include having the new watch perform a deck-level inspection of the vessel. Even in the course of a few hours, cotter pins can disappear, rigging wires can break strands, chafe can develop on sheets, halyards and sails, and stowed gear can come unlashed. This is a good time for a new watch stander to acclimatize to being on deck, although caution should be exercised if the crewmember is coming on deck after a deep sleep.

Items to check at change of watch should be chafe on lines that are loaded including active sheets, guys, halyards and topping lifts. Use a flashlight to see if spinnaker halyards appear chafed where they exit the mast or halyard block. Also check clevis pins that are attached to hardware that’s in motion including goosenecks, boom vangs and outhaul cars.

By taking the time to routinely and thoroughly examine your boat’s safety gear and by keeping it properly maintained, you will ensure the overall preparedness of your vessel in the event of an emergency and will be confident when the unexpected happens while underway.

ADDITIONAL GEAR PREPARATION

Sound Producing Devices Verify operation before start of voyage. Check for extra cans of horn propellant if necessary.

EPIRBs and PLBs EPIRBs and PLBs should have a dated sticker on them showing battery replacement intervals. Verify operation using test features on the device.

SEND Devices Use messaging function to send a test message to your email account. Replace batteries according to MFR recommendation. Most SEND devices specify lithium cells.

Fire Extinguishers Verify the gauge shows “green.” Invert extinguishers several times to free up extinguishing agent. Clearly mark locations of extinguishers.

Anchors and Rode Verify that anchors are assembled and have not been “cut down” to fit in tight places. Assemble rode to anchor. Mouse shackles to prevent pins from unscrewing.

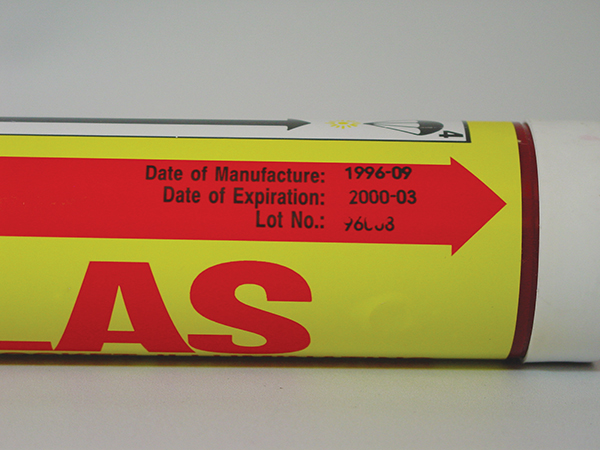

Visual Distress Signals Verify dates on each pyrotechnic. Can be no older than 42 months, 3 ½ years from date of manufacture. Ensure flares are undamaged by water or abuse.

Life Raft Life rafts must be serviced by a factory authorized service center either every 1, 2, or 3 years, depending on the model. Make sure rafts are stored “ready to go” with lanyards attached to a hard point. Replace hydro releases every 2 years.

Abandon Ship Bag (Ditch Bag) Remove all gear from bag and verify operation, battery condition, expiration dates, etc. Verify that ditch bag has a lanyard for security. Update inventory card.

Drag Devices Remove from vessel; check for rot, corrosion, etc. Identify line to be used with device. Flake rode into a bag or box so it can be deployed without knots.

VHF Radios Verify operation of VHF on Channel 68 by asking for a radio check. For boats with masts that are frequently unstepped, check condition of coax connector at the bottom of the mast. Connect using silicon grease for some water protection.