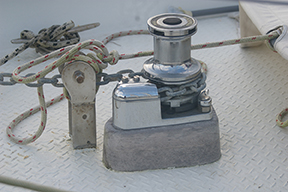

What to consider when installing and operating a new windlass (published November 2013)

So you have spent the money and are now the proud owner of a new windlass. All that remains to do is get the thing to work and then keep it running smoothly. Here are a few points to bear in mind when installing and operating a new anchor windlass.

GOING STRAIGHT

Any windlass will work best if it has a straight and level line of sight from the bow roller back to the chain gypsy. This is really important and getting it right the first time will probably save a lot of grief and frustration, not to mention a lot of additional fabricated gear to compensate for a crooked run. This is an issue that may have influenced your choice between a horizontal or vertical model to begin with (see Heavy Metal Part I in the September 2013 issue of BWS).

Horizontal windlasses tend to be higher and may better suit the required level of your bow roller; a vertical windlass may require an additional backing plate as a spacer to achieve the required height. Adding a backing plate is a good idea anyway as spreading the load over a greater area is only going to benefit the long-term health of your boat. You also need to be confident that the area where the windlass is fitted is structurally up to the task. Many and varied are the ways to reinforce the area, but wood or stainless steel plates seem to be the favorites. If the design of the boat is such that you absolutely cannot get a level run of chain, there are some wonderfully imaginative ways of compensating, but this is truly up to the configuration of your specific windlass and bow roller setup.

If your chain locker is big and spacious, you might be able to mount the unit inside, which has the benefit of keeping it out of the weather. Vertical units have the electric motor and gearbox attached beneath them and this needs to be protected from the chain and saltwater if installed in the chain locker. Nothing will kill a windlass’ motor faster than a regular thrashing with wet metal every time the anchor is raised.

The best solution is to build a permanent barrier between the gearbox and chain, but remember that you will need to access the area for maintenance. A simple but not beautiful solution if your boat allows, is to mount the vertical windlass just aft of the chain locker through the deck. The motor and gearbox are then inside the boat, usually in the V berth or perhaps a sail locker. This of course keeps the machinery out of harms way, dry and accessible. Horizontal models are designed to be mounted on deck and are usually sealed from exposure to the elements.

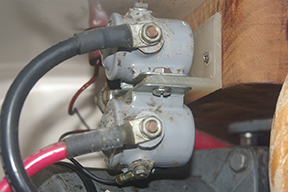

THE SPARK OF LIFE

Windlasses have a large workload and so require a large amount of electricity, big current draws and a long wire run, which means big wire. There is no use spending a lot of money and time on a windlass only to save a few bucks on the cable and compromise the system. If it doesn’t work properly, you haven’t saved a cent. The power rating of your machine and the return distance from batteries to windlass will determine just how much electricity is required, and hence, what size wire, but expect 80 plus amps for a moderate 12 volt system. The windlass will also come with a circuit breaker rated for the unit, and must be installed as close as possible to the driving battery.

Now comes the controversial bit; do I use big, expensive wire for the whole run or install another battery close to the windlass and use smaller cable? The latter works without a doubt and many boats are set up in this fashion, although typically not from the factory. Consider the extra complexity introduced with this method; the battery has to be charged, which means good sized cables need to be run to the charging source via a wire path. The charging system will need to be altered to accept another battery and it needs to be regulated. This might mean an additional splitter, (e.g. Duo Charge), voltage sensitive relay or manual switch. Then you need to find a permanent place for the battery in the bow, secure it well, monitor its condition, maintain it and put up with the extra weight where it is not wanted.

Some boats have the windlass wired in such a way that it will not operate unless the engine is running. Presumably, this is to make sure the windlass has adequate voltage to save on the wire size. But imagine being in a situation where your engine won’t start and you have no option but to pull your ground tackle up by hand. This is precisely the event you wanted to avoid by buying a windlass in the first place. So make sure to take all this into account when deciding on how to wire your windlass.

UPS AND DOWNS

Windlasses can go up and down, all will come up under power and all will go down with gravity. Every windlass will have some type of friction control to let the anchor and chain fall—loosen to go faster, tighten to slow the rate of descent. The best of them will have a band brake that is controlled by a permanently fitted wheel on the windlass, but these are generally found on larger systems.

If you want to power down, then an optional reversing kit is sometimes required depending on the model. This may consist of an extra foot switch or a reversing solenoid that determines the polarity of the electricity supplied and causes the winch to turn in the required direction.

Electric down is slower but more controlled in many instances than letting the anchor and chain free fall. It has the additional benefit of supplying a backup foot switch in case the all-important up pedal fails.

Foot switches are available in two distinct types, ones that carry the entire current or units that supply only a small current to the activating solenoids. What you get will depend on the machine you end up with, but the down switch will mean another hole in the boat, generally in the foredeck. Remote controls, either hand held or fixed are offered by all brands as are numerous other options like chain counters; these spiffy little numbers, when working and calibrated correctly, will conveniently display how much chain or rode you have deployed.

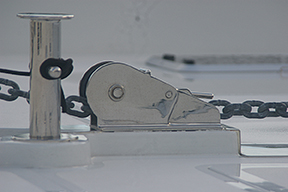

ROLL UP

The primary function of a bow roller is to hold the anchor when it is up and to guide it and the chain in their travels. Some characteristics are obvious; it needs to be big and strong enough to do the job and should be placed free of obstructions. Sounds easy enough, but don’t take it for granted. Double rollers are twice as convenient and may or may not come standard on a lot of production boats. Some bow rollers will have a hinging arrangement to facilitate the anchor, and as it comes in the final bit will pivot to horizontal. Lastly, the roller itself should be able to rotate freely; if not, your chain will gouge the roller and more strain will be put on the windlass.

TAKE GOOD CARE

Windlasses are precisely manufactured pieces of machinery, more or less depending on brand, but all are metal and all use a variety of metals in construction. It is important to remember that dissimilar metals, plus salt water, can cause tireless amounts of corrosion. The best, and perhaps only way to avoid this is by regular maintenance. Pulling the machine apart occasionally and cleaning it is the best way to make sure it does come apart without an angle grinder. Changing the gearbox oil on schedule is another way to lower the odds on the big failure; and always use a snubber (see the September 2013 issue for more on snubbers) or your machine will be operating like a corkscrew in no time.

Anchors and chain are not discriminating, they will happily lay and burrow into all manner of filth and you will have to deal with such filth as it comes on your boat with the chain. A basic solution is the bucket on a rope. While not highly rated, effective or fun, this method is popular all the same. A better solution is the deck wash, which is a pressure pump that supplies seawater to a hose. A deck wash is certainly easier and more fun than using a bucket, but it requires plumbing and power. If you install this at the same time that you install your new windlass, you’ll end up with an easy way to keep your anchor, chain and locker clean.

LISTEN UP

One of the easiest cues to pick up on when using your windlass is the sound it makes when it is loaded up. These powerful and helpful devices are all fitted with circuit breakers to prevent damage in the case of overloading. This precaution is present to protect against abuse from the user.

The secret is to listen to the windlass; the sound of picking up a slack anchor chain is vastly different to that of the machine straining to drag the vessel through the water towards the anchor against 20 knots of wind. When the strain is first detected, break for a few seconds—the chain will sink and the boat move slightly forward, slackening the chain in the process. Then get back on the switch and easily pick up the slack that was created. The machine will sound appreciative, but stop immediately when the strain comes back into the operating sound, allowing the chain to sink again. This process is repeated until the anchor is free of the bottom, when all should be easy unless you have anchored in very deep water with a cheap windlass.

Much the same effect is created by motoring towards the anchor, but most people seem to want to do this at full speed and the windlass may end up trying to pull the vessel backwards and the roaring engine could drown out the winch’s pleading. Helm-located switches encourage this scenario. People who have a manual windlass will know all this intuitively, having been the power source and not wishing to trip their own circuit breakers prematurely.

Whatever windlass you choose to buy, install and cruise with is entirely up to you and the needs of your boat and sailing plans. But installing, operating and caring for your new and expensive windlass properly will ensure that it gives you years of trouble free service.

John Champion has lived aboard since 1999 and sailed half way around the world in the process. He currently floats around in Langkawi, Malaysia and offers appraisals and surveys for production boats in the region. If you are thinking of buying a boat in SE Asia he can be contacted at, jwchampion@live.com.au.