Switching out our old holding plate system for a modern and efficient evaporator plate unit (published April 2015)

During a few weeks of sailing in the Florida Keys, and just when Jill and I thought we were done with the refit and restoration of our Pearson 424 S/V Regina Oceani, our last legacy system, the 12-volt refrigeration, failed. While the problem was not serious, and we had the redundant engine-driven system, it was time to consider upgrading our 1960’s ice cream truck technology.

ASSESSING THE OLD

Our old refrigeration system used holding plates. In terms of total energy usage—measured in horsepower, watt hours or amp hours—holding plates are the most efficient method of maintaining a refrigerated space. Although a very old technology, they are still in use in refrigerated semi trailers and street corner ice cream carts. Simply stated, it works well.

The system freezes a tank full of liquid, called the eutectic fluid, which soaks up heat until the fluid is unfrozen. Then repeat. Just like an ice cube in a drink where the drink stays at the same temperature until the ice is all melted, the holding plate holds its temperature until it’s completely unfrozen. The state change from solid to liquid absorbs a tremendous amount of energy, so it takes a long time. A well-designed 12-volt holding plate system will cycle about twice per day and will run for less than an hour each time (longer or more often in a warmer climate). The total amp hours drawn from the batteries each day are minimal for the amount of cold you get in return.

Used at the dock, a 12-volt ½ HP refrigeration compressor is unbeatable. Similarly, an engine-driven compressor freezing the holding plates while running the engine for other reasons is fast and efficient. But there are two hidden problems here.

First to the engine-driven system, this is a sailboat. We can go days without running the engine for propulsion and running it just to charge batteries or to freeze holding plates is inefficient and just moves the clock closer to the next engine overhaul. So we end up using the 12-volt system most of the time and try to remember to top up the holding plates whenever the engine is running.

But now comes the really tough part—while the 12-volt system uses fewer total amp-hours per day, it uses them all at once. To understand why this is a problem, a few properties of batteries must be understood.

BATTERY BASICS

We have two 4D size AGM (absorbed glass matt) house batteries each rated at 210 amp-hours. The ½ HP refrigeration compressor draws around 36 amps when running. With 420 amp-hours of capacity in the battery bank, how would drawing 36 amps for say 45 minutes twice per day be a problem? First we have to understand how batteries are rated and then a little bit about how they actually behave.

The rating of a deep cycle battery like those in our house bank indicates the total number of amps that could be delivered over a period of 20 hours. In this case, that discharge rate would be 10.5 amps (210 amps/20 hours = 10.5 amps). For the bank with two of these batteries in parallel, the draw rate could be 21 amps over the same 20 hours. But batteries are not linear in their behavior. Peukert’s Law tells us that the faster the current is withdrawn from a battery, the fewer total amps are available from the battery. Conversely, the slower the current is withdrawn, the more total amps are available.

With the exception of Lithium Ion batteries, which have many other special considerations and are still beyond our budget, there are two other factors of battery behavior that must be understood and respected: depth of discharge and rate of charge.

Yet another rating of batteries is the number of deep discharges they can endure. To manage batteries for the longest usable life, they should not be discharged beyond half way. Which makes that 420 Amp-Hr bank now a 210 Amp-Hr bank. But wait, it gets worse.

Charging a battery is like pushing a boulder up a hill that gets steeper and steeper. It is fairly quick to charge a battery to 80 percent of its capacity. After that the charging rate of the battery slows down dramatically. If you are burning fuel to charge batteries, topping up the batteries can be very expensive. Given these factors, the battery bank should be managed between 50 and 80 percent of discharge. That only leaves 30 percent of the original 420 Amp-Hrs or 126 Amp-Hrs as the useful efficient capacity of this “420 Amp-Hr” battery bank.

Now back to Peukert. If this bank is discharged at a 40-amp rate, the total number of amps available goes down to around 380 amps. The usable 30 percent of that would only be 114 amps. If the refrigeration uses about half of that, there is not a lot left for the autopilot, lights, stereo, etc. before its time to charge the batteries again.

Conversely, if the discharge rate were only around 11 Amps, the total capacity of the battery bank would be around 465 Amp-Hrs. The usable 30 percent would be about 140 Amp-Hrs, 23 percent more capacity, which is almost like having another half battery!

THE NEW SYSTEM

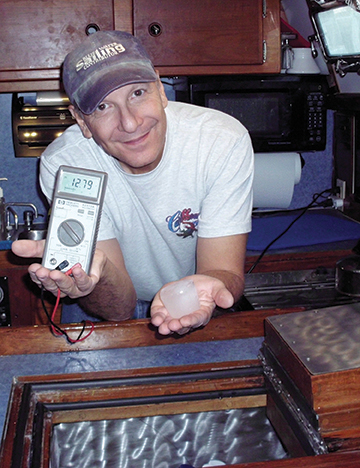

After assessing all our options, we changed out our old refrigeration system for a modern evaporator plate system that runs more frequently but draws much less current while running. The new system also provides more consistent temperatures than the holding plate system, weighs a lot less and takes up less space in the ice box and in the lockers. Our old 12-volt compressor was water-cooled so could only be used while in the water. At our dock on the Eau Galle River in Melbourne, Florida, the nutrient-rich waters clogged our water strainers every few weeks.

Water-cooling is more efficient than air-cooling, but why not have both, or better yet, the option of using both? This would allow us to disable the water pump when at the dock or on the hard and not worry about clogged strainers or spoiled food. On a cruise in cleaner waters we can enable the water pump and improve the efficiency of the system.

To select a system, we had to consider where the compressors (one for the freezer and one for the refrigerator) would be located and how to keep them cool. In our case this was under the main berth, presenting a special problem—how to get cool air in and hot air out from the under-berth locker? One system finally stood out as offering all the features we needed: high capacity for our large box, ducted air cooling with optional water cooling and variable current draw levels.

Two Sea Frost BDXP systems fit in a little less space than the single 12-volt belt-driven compressor system and weighed 60 pounds less. After sending the dimensions of the icebox to Cleave Horton, he quickly sent back a scale drawing showing the recommended evaporator plate and refrigerant line layout. Removing the old three-inch thick holding plates added a full cubic foot to the freezer and lightened the boat by an even 100 pounds. I fashioned a new solid foam divider out of four layers of hard insulting foam from the home improvement center and wrapped it in two layers of fiber-reinforced aluminum duct tape.

The only other information I had to provide Cleave besides a credit card number was the distance from the icebox to the compressors. The systems arrived with the plates mounted on plywood sheets and all lines were pre-charged. Installation consisted of routing the lines and connecting them with a pair of wrenches—no vacuum pump, Freon charging, etc.

Incoming air came flowing through two four-inch flexible ducts tied to flanges on the galley/aft cabin bulkhead, within the under-berth locker. Two air conditioner vent/deflectors were used to allow air into the galley under-sink locker thus allowing plenty of air to flow back to the ducts. To exhaust the warmer air from the compressors, I cut holes in the floor of the locker to allow the exhaust air to flow into the bilge. The bilge is open to the engine compartment and is vented by two large air vents in the top of the transom coaming.

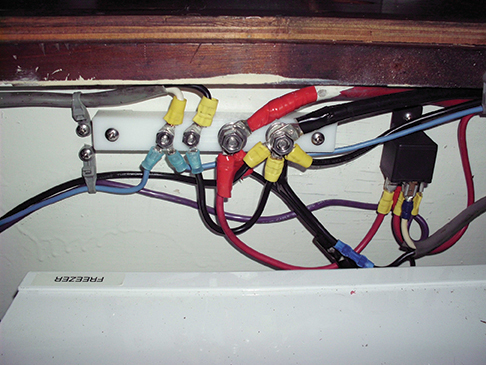

For electricity, the old system’s wiring was rated at 50 amps and had more capacity than we needed. It runs directly from the battery through a dedicated bulkhead mounted circuit breaker to the locker. To be able to conveniently switch the refrigeration on and off from the nav station, for example if having difficulty getting a shortwave transmission through due to electrical noise from the compressors, I installed a 30-Amp automotive type relay in the under-berth locker with a fused remote switch at the nav station controlling the coil of the relay. I also ran the positive and ground wires through some inductive choke rings to hopefully lower any electrical noise that might be induced back into the power lines and affect short wave radio transmissions.

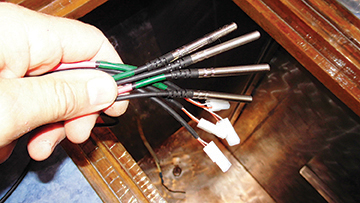

Sea Frost offers a variety of thermostatic control options. We chose the digital thermostat with remote sensors for box temperatures, adjustable speed settings, and remote compressor run and fault LEDs. Most of the time we leave the controls in automatic mode but the manual modes can be selected to draw between 4.5 and 7.7 amps. One water pump feeds both compressor units, draws just under one amp, runs only when one or both of the compressors runs and can be switched off from switches on the compressor enclosures. These switches could easily be remotely located for more convenient access.

With 400 watts of solar panels, we find that we can pretty much keep up with the refrigeration power needs and then some. Add the wind generator and offshore our towed generator and we can keep up with most all our power usage without doing any dedicated charging. Occasional engine use for propulsion tops up the batteries quickly and while sailing or at anchor if needed, we can run our separate 6-HP diesel 12-volt generator/SCUBA compressor to top up the batteries while only burning about a pint of diesel per hour. Life aboard is better now with lower current draws, happier batteries, cold beer and hard ice cream. And that’s the truth.

For over a decade now, Pete Dubler has been writing for BWS about projects on his Pearson 424 including articles in this series detailing her complete restoration and refit. During 2015, under a phased retirement program, Pete and his wife Jill will spend more time shaking out S/V Regina Oceani and plan to depart for worldwide cruising December 2015.